ABOUT US

ABOUT US

ZHEJIANG DUNTUOTECHNOLOGY CO.,LTD.

Duntor Technology, a high-tech private enterprise integrating design, R&D, production, sales and service of advanced engineering tools, with an annual output of more than 5 million pieces of various engineering tools, and its products cover all kinds of tools for road milling machines Knives for rotary excavators, cutters for coal mining machines, various mining drill bits, rock drilling tools, bucket teeth, tooth seats, etc. The company manufactures high-quality engineering tools with its unique technology, advanced equipment and strict management, and provides solutions and quality services to customers around the world.

product

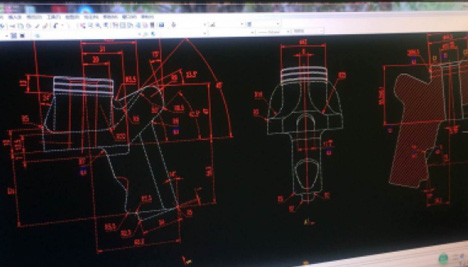

technology advantages

Cemented carbide and steel are closely combined to deal with the most severe external load impact

Shield Tool is composed of cemented carbide and steel: cemented carbide is used for the tip of the pick to wear easily, and steel is used for the pick head and tooth shank. In order to make the two materials closely connected for a long time, the shield Tuo has developed its own unique process method and ultrasonic detection equipment. Through the ultrasonic detection of the two materials, the production data can be monitored and recorded. In addition, ultrasonic detection can also detect the shear strength.

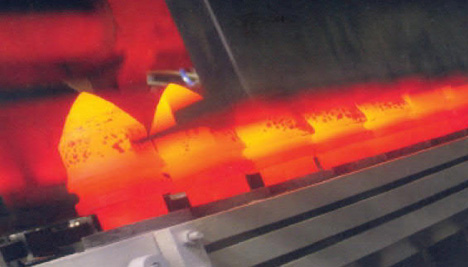

This investment is very worthwhile in the harsh employment environment. The tool will become very hot during use. Because the cemented carbide and the steel of the tooth body are of different materials, they have different expansion properties when heated, so they will generate extremely strong tensile forces. This is when the BOFENG special brazing filler metal comes into play. It makes the cemented carbide and the tooth body steel firmly and tightly combined. The brazing filler metal absorbs the tensile force and keeps the two closely connected, thus ensuring that customers will not waste replacement time due to tool breakage.

Enterprise

Video